E5AN-HT, E5EN-HT

Programmable Temperature Controller (Digital Controller) (96 x 96 mm and 48 x 96 mm)

Programmable Controllers Join the Series! Program up to 256 segments and take advantage of the high cost performance of the new LCD that improves both the field of view and contrast.

* Information in this page is a reference that you created on the basis of information in the product catalog before the end of production, may be different from the current situation, such as goods for / supported standards options / price / features of the product. Before using, please check the compatibility and safety system.

last update: December 19, 2013

Programmable Models Now Added to the Series, Which Already Has Three Million Controllers in Service

The new models carry on the simple operation and low cost of the series.

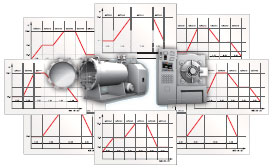

A wide variety of applications can be handled by using program settings with up to 256 segments.

High-level of Basic Performance to Meet a Broad Range of Needs

High Precision

Thermocouple or Pt: ±0.1% PV,

Analog input: 0.1% FS

High-resolution for Measurements, Fluctuation Detection, and Logging of Temperature and Humidity in Environmental Testing Equipment

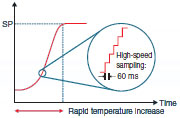

High-speed Sampling Period

Sampling Rate Sufficient to Handle Rapid Increases in Temperature

Stable Control of Objects Requiring High-speed Response by Handling Rapid Increases in Temperature, Such As for Ceramic Heaters

Five Digits and K Thermocouple

Five-digit PV/SV Display to 0.01°C for High Performance

Display to 0.01°C for Pt, K, J, or T.

Enables high-precision temperature control.

Programmable Models Added to Lineup to Support a Broader Range of Applications

Up to 256 Segments

You can program up to 8 programs × 32 segments.

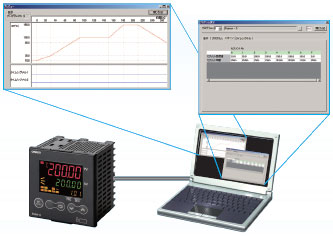

The CX-Thermo Support Software (Sold Separately) Enables Easy Setting and Control of Programs.

High Cost Performance Makes Selection Easy

Best Value in a Programmable Temperature Controller at an Affordable Price.

Easy Setting and Monitoring

Easy Parameter Setting on a Computer Using the CX-Thermo (Sold Separately)

Using the trend monitor enables easy adjustment and maintenance.

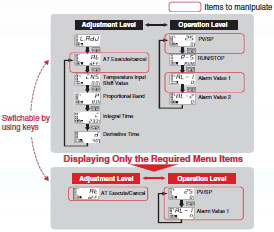

Parameter Masking

Customize the menu display to match the worksite. Display can be turned OFF for parameters that are not necessary to better match the worksite.

This helps prevent incorrect operation for both the operator and the Controller.

Infrared Communications Port

Perform communications with a computer by using the infrared communications port on the front panel (except for the E5CN-H and E5CN-HT). The ability to use CX-Thermo from the front panel after the Controller has been mounted to a control panel reduces maintenance time.

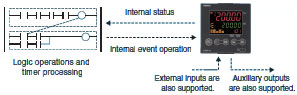

Easy Logic Operations

Easily perform logic operations without a PLC.

Effectively use limited I/O by combining I/O bit status and alarm status through AND and OR logic operations or by inverting event input logic.

New Liquid Crystal Display Provides Superior Visibility

New, High-visibility Display That Is Ideal for High-performance Temperature Controllers

last update: December 19, 2013

Product Category

Product Category

Control Components

Control Components

-

Temperature Controllers

Temperature Controllers

-

Discontinued

- E5AN-HT, E5EN-HT

-

Discontinued

-