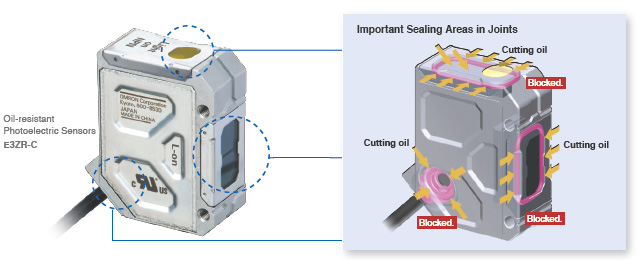

E3ZR-C

Oil-resistant Photoelectric Sensors

Photoelectric Sensors That Withstand Cutting Oil to Reduce Failures Caused by Ingress of Cutting Oil

last update: September 1, 2016

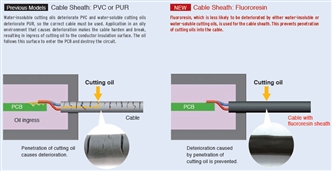

No Cutting Oil Ingress by Any Path The Strongest Material Cables with Fluororesin Sheaths

The results of a thorough analysis of the ingress paths of cutting oil show that the deterioration of cable sheaths is a large factor.

The cable sheaths of OMRON’s Oil-resistant Components are made from fluororesin materials to provide maximum protection against the deterioration with a unique new concept. The result is an oil resistance impregnable to even highly aggressive cutting oils.

Fluororesin Blocks Ingress from Cables

[Patent Pending] Fluororesin Outer Cable Sheath

Fluororesin, which provides superior resistance to corrosion, is used for the outer cable sheath to suppress cable swelling and deterioration and prevent the ingress of cutting oil into the PCB inside the Sensor.

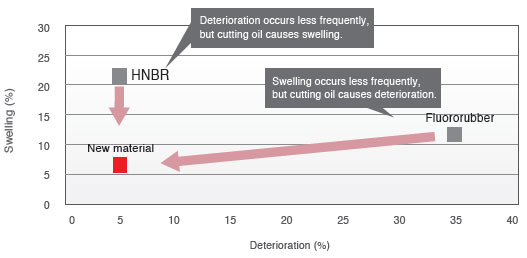

No Cutting Oil Ingress by Any Path The Strongest Material New Rubber Material Combining HNBR and Fluororubber

In addition to deterioration of cable sheaths, deterioration of the rubber used at joints and moving sections is also a major cause of ingress of cutting oil. In order to prevent rubber deterioration, OMRON’s Oil-resistant Components use a new fluorinated rubber at joints and moving sections. Combined with fluororesin cables, this double use of the strongest materials forms an impregnable wall of oil resistance.

OMRON-developed Rubber Blocks Ingress through Joints and Moving Sections

[Patented] New Rubber Material Combining HNBR and Fluororubber

Hydrogenated nitrile butadiene rubber (HNBR), which provides superior resistance to oil, was blended with fluororubber in a unique OMRON compound to develop a new rubber that provides superior resistance to both swelling and deterioration due to cutting oil.

It is used in seals for joints and moving sections that prevent ingress to prevent deterioration and destruction of the seal due to cutting oil, resulting in increased oil resistance performance.

This new material combines the benefits of HNBR and fluororubber

*The Strongest Material: Based on June 2016 OMRON investigation.

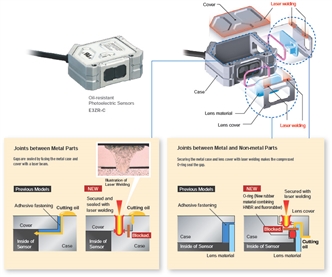

No Cutting Oil Ingress by Any Path Advanced Sealing Method

In addition to cable sheaths, joints, and moving sections, cutting oil enters most easily in gaps between different materials. OMRON’ s Oil-resistant Components completely block the ingress of cutting oil with a state-of-the-art sealing method that does not allow the creation of gaps.

Completely Sealed with Laser Welding

[Patent Pending] Method for Complete Sealing without Adhesive

The gaps at joints between metal parts are sealed by fusing the metal parts together with the laser beam.

At other joints, O-rings of the new material are used and the circumference is fastened with laser welding to prevent ingress of cutting oil without any adhesive which can cause swelling and deterioration.

The laser beam is controlled with high precision. This method of fusing metal at a precise location with a small laser beam spot enables application to sensors and other small electronic devices.

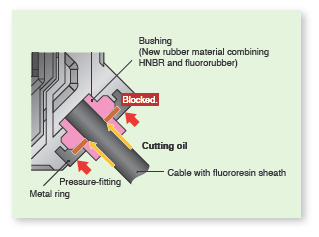

No Cutting Oil Ingress by Any Path Unique Structure

In addition to cable sheaths, joints, and moving sections, cutting oil enters most easily in gaps between different materials. OMRON’ s Oil-resistant Components completely block the ingress of cutting oil with a unique structure that does not allow the creation of gaps.

OMRON’s Unique Structure without Gaps Blocks Oil Ingress

Mechanical Seal Structure

A bushing made from the new material is compressed and deformed by pressing a metal ring against it to tighten and seal the fluororesin cable.

This prevents the ingress of cutting oil through the cable lead section.

last update: September 1, 2016