Our i-BELT Data Services assist in linking the production and management challenges with manufacturing data. The data is turned into meaningful information to achieve practical improvements and to solve your production challenges

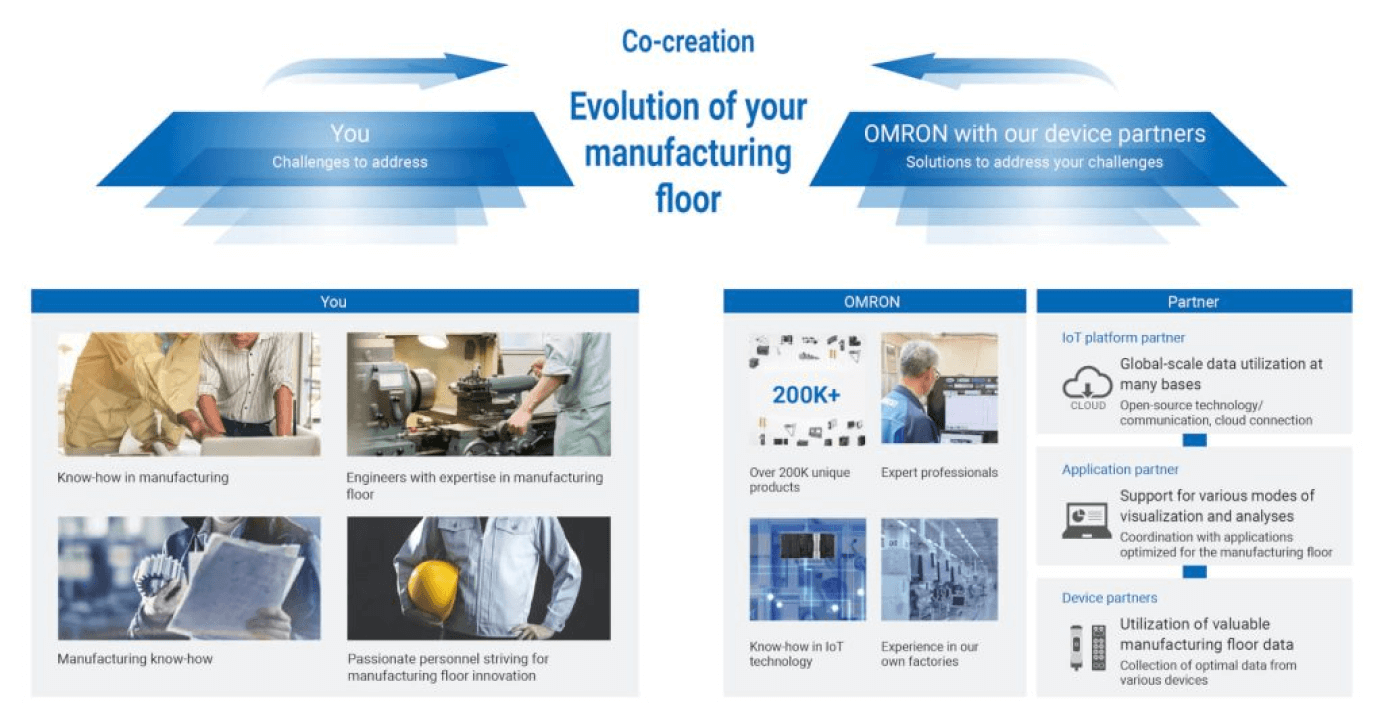

OMRON is your co-creation partner that realizes continuous improvement of the production site.

With the development of IoT, AI and robotics, the evolution of manufacturing is highly anticipated. On the other hand, many companies are facing severe issues, such as the scarcity of technicians who are indispensable for the evolution of manufacturing, and the growing shortage of labor, diversification, and high energy costs. Maintaining manufacturing and strengthening competitiveness has become a top priority.

With our i-BELT Data Services, we co-create the acceleration of digital transformation, sustainable production and energy management together with our customers to continuously innovate the art of manufacturing.

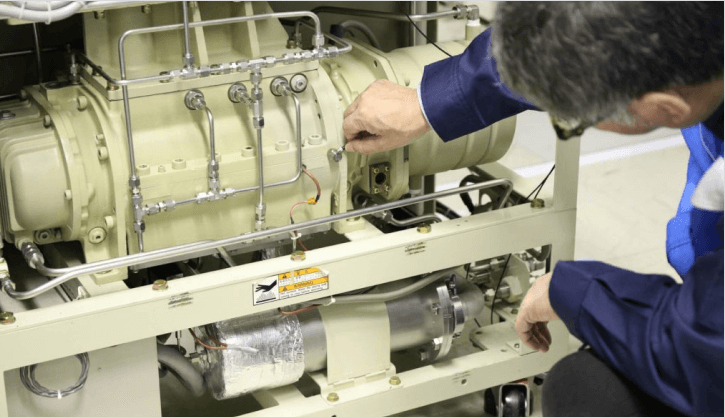

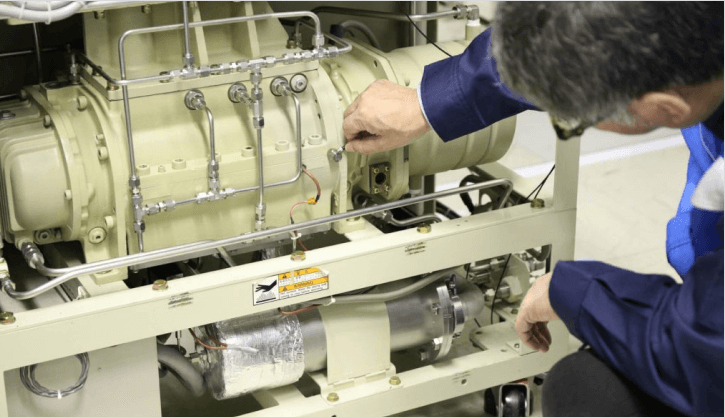

Working together with you, our manufacturing and data experts identify and examine your production and management challenges. We strive to continue innovating your manufacturing process by merging your know-how & experience with OMRON’s unique know-how, technology and products.

We help customers to attain flexible, people and environment friendly production that is quickly adaptable to changes through:

Read more on converting manufacturing floor data into a management advantage.

Download Now

Download Now

Case Studies on data utilization service for

manufacturing floor

Download Now

Download Now

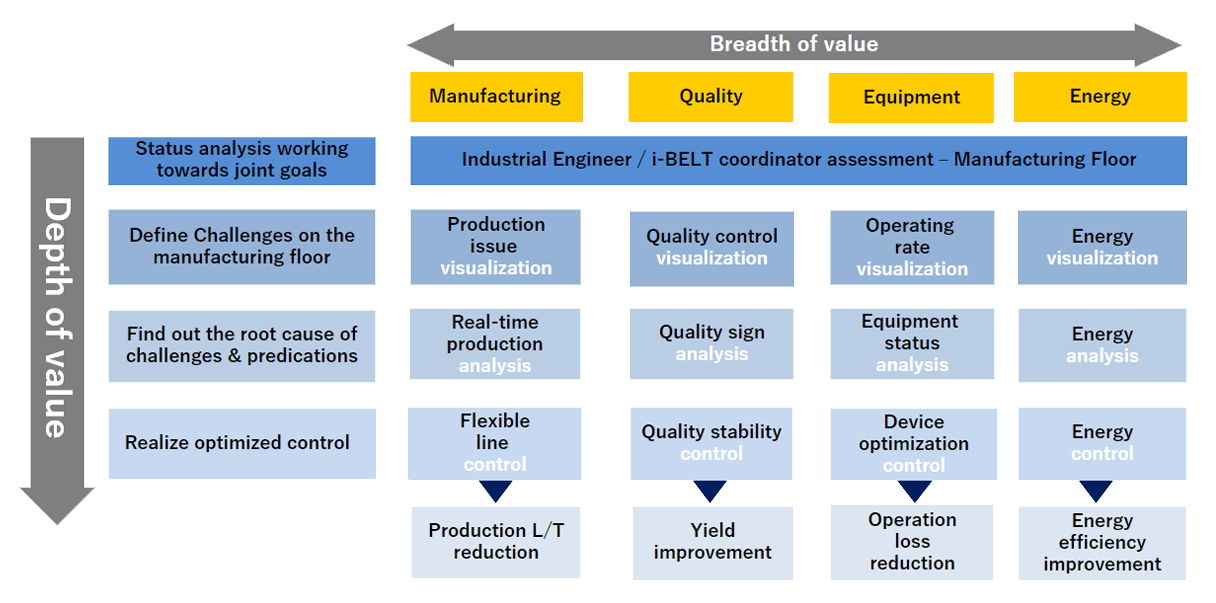

We will provide a plant examination service in four value categories (manufacturing, quality, equipment, energy) to tackle your challenges. We extract issues through visualization and analysis, and provide services, such as improvement assistance and automation, suited to different phases and needs.

In order to simplify the efforts from both sides, we follow a step-by-step approach so that we understand customer’s challenges deeply and plan the future roadmap together with our customers while minimizing the initial investments for them.

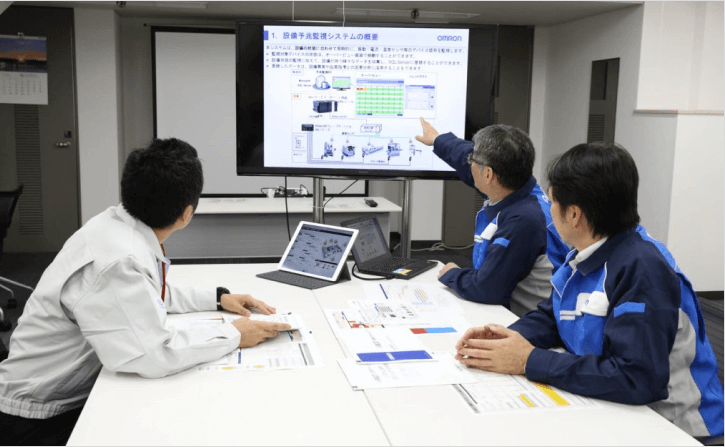

By consultancy and workshop methodology, we survey customers’ challenges and operating state (data collection, quality, production budget, load time, etc.). We measure the required data for estimation, discuss about improvement potential, and propose a draft evolution scenario.

We start with extensive data analysis and then facilitate the “visualization” to provide an improvement estimation and offer assistance in determining targets and future roadmap.

In this step we build an extensive dashboard to continuously monitor manufacturing process. We promote process innovation to ensure customer’s goals are achieved.

In this step, OMRON and customer engages in a partnership to continuously improve upcoming challenges. We continue to promote manufacturing floor innovation to attain customer’s goals by making use of various improvement processes and systems developed in our factories and labs.